|

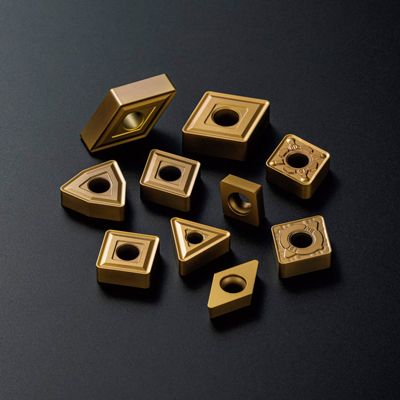

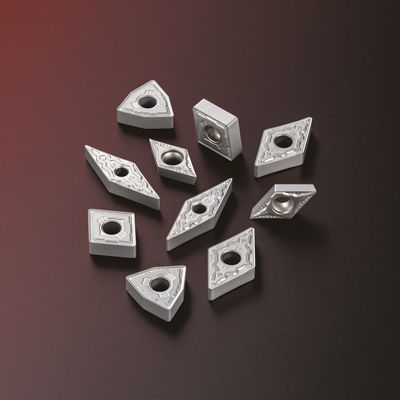

Maximum Tool Life in Turning AC9115 and AC9125T grades set new standards in turning. By utilizing state-of-the-art coating technologies and optimized substrates, these tools offer exceptional performance and reliability. Your Advantages at a Glance: Extended Tool Life: Thanks to an innovative coating technology, the tool life is significantly increased. This leads to fewer tool changes and therefore higher productivity. Reduced Built-Up Edge (BUE): The special WC-based coating minimizes the adhesion of titanium and other materials. This reduces BUE formation and ensures a more stable cutting process. Excellent Wear Resistance: Compared to uncoated carbide grades, AC9115 and AC9125T offer significantly higher wear resistance. This allows for the use of higher cutting speeds and feeds. Versatility: AC9115 is particularly well suited for continuous cuts, while AC9125T excels in interrupted cuts and demanding machining conditions. Technology in Detail: The AC9115 and AC9125T grades benefit from a multi-layer coating specially developed for the high demands of turning. This coating ensures:

With the AC9115 and AC9125T grades, you invest in tools that increase your productivity and reduce your machining costs. Benefit from longer tool life, reduced BUE formation, and increased process reliability. |

Haven't found what you're looking for?

Then please send an e-mail with a description of your optimization requirements to: turning [at] sumitomotool [punkt] com