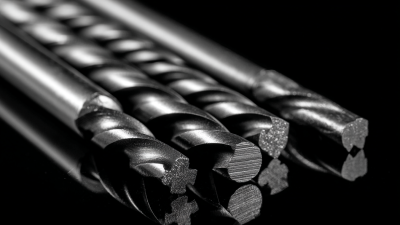

In the realm of precision machining, Carbide Drill Bits have emerged as indispensable tools across various industries, providing unparalleled durability and efficiency. According to a recent report by the International Organization for Standardization (ISO), the global market for carbide tools is projected to reach $15 billion by 2026, indicating a significant demand driven by advancements in manufacturing technologies.

Carbide Drill Bits are renowned for their ability to withstand high temperatures and extreme wear, making them ideal for applications in sectors such as aerospace, automotive, and construction. As businesses strive for higher productivity and cost-effectiveness, understanding the diverse applications of Carbide Drill Bits becomes crucial for engineers and manufacturers alike.

This guide aims to elucidate these applications, helping professionals make informed decisions to enhance their operational efficiency and output quality.

Carbide drill bits are renowned for their exceptional durability and precision, making them an essential tool across various industries. The unique properties of carbide, such as its hardness and resistance to wear, allow for longer tool life and the ability to withstand high drilling temperatures. Reports indicate that the carbide tools market is projected to grow significantly, driven by the increasing demand for high-performance drilling and milling applications. In fact, the drilling tools segment alone is anticipated to capture a substantial market share due to advancements in drill bit technology and innovative designs.

In practical applications, the versatility of carbide drill bits allows them to effectively tackle a wide range of materials, from masonry to metal. For example, recently launched products have incorporated multi-grind heads that enhance cutting efficiency for both concrete and brick. Furthermore, new designs addressing challenges faced in abrasive rock drilling exemplify the ongoing innovations in the industry. These advancements not only improve operational efficiency but also offer significant time savings in project completion. As industries continue to seek greater productivity and drilling effectiveness, carbide drill bits will remain a crucial tool, fostering growth and technology enhancements in the manufacturing landscape.

| Industry | Application | Key Features | Benefits |

|---|---|---|---|

| Manufacturing | Metal Drilling | High hardness, wear-resistant | Long tool life, high precision |

| Construction | Concrete Drilling | Tungsten carbide tip | Efficient in hard materials |

| Aerospace | Aluminum Drilling | Chipped design, reduced friction | Smooth finish, longer performance |

| Automotive | Engine Block Drilling | High heat resistance | Improved efficiency, better output |

| Mining | Rock Drilling | Heavy-duty design | Durability in tough conditions |

Carbide drill bits are essential tools across various industries due to their durability and precision. In the manufacturing sector, they are commonly used for drilling hard materials, such as metals and composites, which are prevalent in automotive and aerospace applications. The ability of carbide bits to withstand high temperatures and resist wear makes them ideal for tasks that involve high-volume production and intricate components, ensuring efficiency and reducing downtime during machining processes.

In the construction industry, carbide drill bits are favored for their capability to penetrate tough substrates like concrete and masonry. Their strength allows for the installation of fixtures, anchoring systems, and pipelines, contributing to the structural integrity of buildings and infrastructure. Furthermore, in the electronics sector, these drill bits are vital for creating fine holes in circuit boards and other delicate components, demonstrating their versatility across varying scales and complexities of projects. Each industry leverages the unique properties of carbide drill bits to enhance performance and achieve specific drilling solutions.

When selecting the right carbide drill bit for your project needs, it’s crucial to consider the specific materials you will be drilling. Carbide drill bits are designed to withstand high temperatures and maintain sharpness, making them ideal for tough materials such as metal, concrete, and dense wood. Choose bits with different coatings, such as titanium or cobalt, for added durability and performance tailored to your project.

When selecting the right carbide drill bit for your project needs, it’s crucial to consider the specific materials you will be drilling. Carbide drill bits are designed to withstand high temperatures and maintain sharpness, making them ideal for tough materials such as metal, concrete, and dense wood. Choose bits with different coatings, such as titanium or cobalt, for added durability and performance tailored to your project.

Tips: Always match the drill bit size with the diameter of the hole you need to create. For example, a larger hole may require a step drill bit, while intricate designs could benefit from a smaller, precision bit. Additionally, be mindful of the drill bit's flutes; fewer flutes are better for chip removal in softer materials, while more flutes are suited for harder substances.

Another essential aspect is the drill bit's geometry, which directly affects its performance. Bits with a pointed tip are beneficial for starting holes accurately in harder surfaces, while those with a more blunt tip work well in softer materials. Evaluate your project's requirements carefully, and don’t hesitate to invest in high-quality carbide bits; the right choice can significantly enhance your project’s efficiency and quality.

To ensure the longevity and optimal performance of carbide drill bits, regular maintenance is crucial. One important tip is to always clean the bits after use. Residues of various materials can accumulate on the surface, affecting their cutting efficiency. A simple cleaning using a soft brush or a cloth can remove debris and prevent rust, which is essential for maintaining their sharpness and prolonging their lifespan.

Another critical aspect of maintaining carbide drill bits is proper storage. Storing bits in a dry environment and using protective cases can shield them from moisture and physical damage. Additionally, avoiding contact with harder materials during storage will help prevent dulling of the cutting edges. It’s also beneficial to periodically inspect the bits for wear and tear, as early detection of damage can prevent more serious issues down the line, ensuring that your investment in high-quality carbide drill bits remains worthwhile.

This bar chart illustrates the distribution of carbide drill bit applications across various industries. The construction and manufacturing sectors lead the usage, indicating the importance of high-quality drill bits in these fields for efficient operations.

When it comes to drill bits, carbide options are often hailed for their superior hardness and longevity in various industrial applications. Compared to conventional steel or high-speed steel (HSS) drill bits, carbide drill bits maintain a sharper edge for much longer, making them ideal for drilling into harder materials such as stainless steel, wood, and composites. This durability translates into greater efficiency and cost-effectiveness over time, as users reduce the frequency of replacements and downtime.

However, carbide drill bits also come with drawbacks that should be considered. They are generally more brittle than their steel counterparts, meaning they can break under excessive pressure or when used incorrectly. Additionally, carbide bits tend to be more expensive upfront, which might deter some users, especially for applications where softer materials are involved. In such cases, high-speed steel drill bits might offer better versatility and ease of use, especially in less demanding environments. Ultimately, the choice between carbide and other types of drill bits hinges on balancing performance needs, material hardness, and budget constraints.